In a previous post, you noted that most important aspect of

a system running on solar energy is how much power system consumes vs. how

much power the solar panel generates; the last variable can be found from the

data sheet of the solar panel at hand. The solar panel is made of a module, or

electrically inter-connected multiple modules on the same frame where the solar

module(s) are encapsulated to protect them from corrosion. Each solar module is

made of multiple solar cells inter-connected in series or parallel with a

certain packing density. This post is not meant to discuss the fabrication of

solar panel, but more on how to read the electrical properties found in the data sheet....We

will touch on the mismatch happening when connecting multiple panels in an

array using a practical example comparing output power from two identical solar

panels.

First let us talk about the electrical properties of the

solar panels: In the picture below, we have two solar panels, from different

manufacturers, the bigger one is 350*255mm(W*H) rated at Pmax=10W at a voltage

17.8V. The smaller one is 250*134.5mm(W*H) rated at Pmax=3.5W at a voltage of

6V. Battery charging is a current dependent action not a voltage dependent

action; assuming that you have a solar charger implementing Maximum Power Point

Tracking (MPPT) algorithm, your most important variable is how much current you

are getting from the solar panel...

|

| Electrical Spec. for 10W Solar Panel |

|

| Electrical Spec. for 3.5W Solar Module |

Once you note that the electrical proprieties shown in the

picture above, you will find that both panels generating the same current at

Ipmax, more or less. Let us try to test these panels in practice connected with

a solar charger, the Sunny Buddy by Sparkfun. As per hookup guide provided for

this solar charger, you have the option either to check how much the solar

panel is delivering current or you can see the how much the charger is

supplying current to the battery, where the later depends on Maximum Power

Point Tracking algorithm to guarantee maximum power transferred to the battery

guaranteed no damage happening to battery. Let us follow instructions found at

Sparkfun Sunny Buddy hook-up guide to check how much current each solar panel

is delivering....”A useful trick for monitoring the input current of a single

panel system is to clear JP1 and close JO2, then connect an ammeter between the

+ pads on the two 3.5mm footprints. This will allow you to monitor the current

draw from the solar panel. Note that JP1

must be resoldered and JP2 reopened before attempting to use the sunny buddy without

the meter in place!”

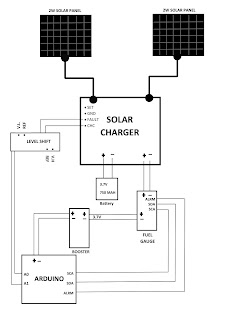

In above video, we are not using a solar charger to deliver power to the DC motors but using a nano power energy harvesting power supply based on the LTC3588-1, breakout is made by sparkfun and below circuit diagram is a snap shoot taken from the application information section of the LTC3588-1 data sheet.

The video for the solar car, two circuits, similar to

figure-11 above, are soldered on the board mounted above the car. Unlike the

circuit suggested in the application information, no back batteries were

connected to the circuit; in the input side there is a solar panel and output

of the IC has a super capacitor plus the load (DC motor) connected in parallel.

The solar charger used here, the Sunny Buddy, can be set to

reduce its current draw once a certain input voltage is reached, where this

voltage can be set via a potentiometer, I did not try to optimize this setting

while measuring the current drawn by the solar charger. Here is a summary of

the result:

Item

|

Dim.(W*H)(mm)

|

Rated Power(W)

|

Vmppt(V.)

|

Imppt(A.)

|

Itest(A.)

|

Solar panel #1

|

350*255

|

10

|

17.8

|

0.57

|

0.46

|

Solar panel #2

|

250*134.5

|

3.5

|

7.2

|

0.583

|

0.504

|

The current readings measured via the multi-meter are close

to what the electrical properties section is showing for Ipmax , but the

current drawn from the smaller solar panel is slightly more than that current

drawn from the larger solar panel and the reason is the difference in voltage

rating of each panel. This difference is due to the way the solar cell is inter-connected

inside the solar module; it is up to you and solar charger to draw maximum

current from solar panel.

Now, let us turn our attention to the issue of mismatch. On

a module level, strings of solar cells are connected in series or parallel to

produce the required current or voltage. Ideally the solar cells are identical

but in practice they will be a mismatch between them which will affect the current

or the voltage produced depending if the cells are connected in series or

parallel. Thus, you will see the +/- tolerance in the electrical properties

section of data sheet. Likewise, the solar panels can be electrically inter-connected

to form strings and arrays of panels to produce required current or voltage, in

this regard; any mis- match between the solar panels will affect the current or

voltage of series and/or parallel combination. The mismatch happens due to the

fact that you will not get exactly the same output power from different panels

even if they are rated the same, manufactured in the same way and even fabricated

by the same manufacturer. Check this video below showing two identical solar

panels, rated at 2 watts each, connected

to run two motors, each motor is on one side of a plastic car; if the car goes straight

then both solar panels are producing the same amount of power. Note that these

panels are identical, from same manufacturer and rated at the same voltage and

power.

As discussed above, the power extracted from a solar panel will depend on how you extract it, either using MPPT or other solutions, like linear regulators, switching regulators or any energy harvesters.

As discussed above, the power extracted from a solar panel will depend on how you extract it, either using MPPT or other solutions, like linear regulators, switching regulators or any energy harvesters.

In above video, we are not using a solar charger to deliver power to the DC motors but using a nano power energy harvesting power supply based on the LTC3588-1, breakout is made by sparkfun and below circuit diagram is a snap shoot taken from the application information section of the LTC3588-1 data sheet.

|

| Curtsy of LTC-3588-1 Data Sheet |

We will explain more on the LTC3588 in future posts... stay

tuned to know more.......