Couple of years ago, Anaren marketed a radio frequency chip with

an integrated antenna working at 900Mhz and based on Code Division Multiple Access

Technology (CDMA) technology. Their product was based on Texas Instruments (TI)

cc1110 chip and thus TI supported Anaren to market the booster pack board. In

addition to anaren RF chip, the booster pack included a board having a

prototyping area and a space to place a TI msp430 microcontroller. Off course,

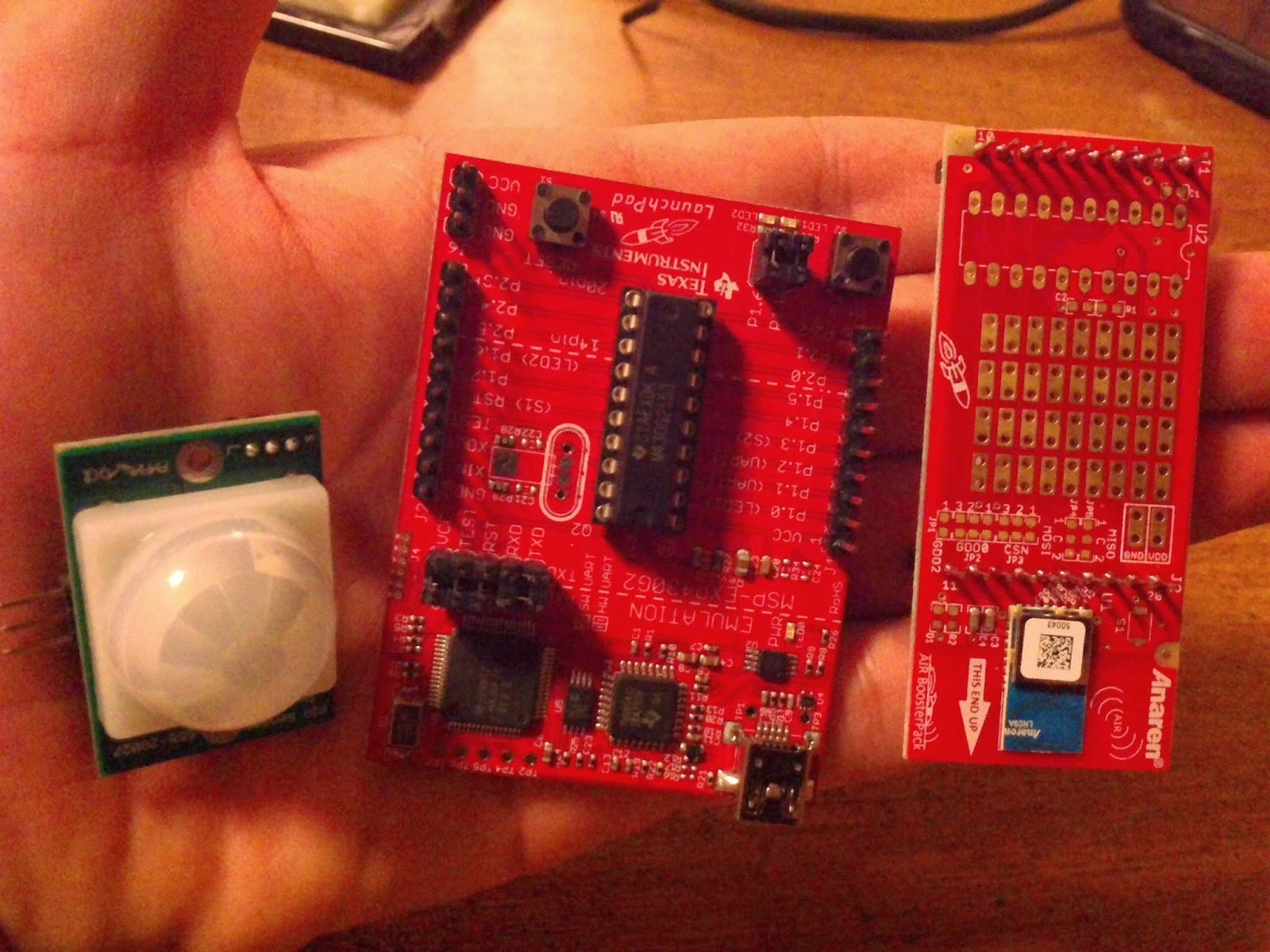

Anaren’s booster pack would best work with TI msp430 Launch Pad, see pictures

below.

|

| Figure 1 from right to left Anaren booster pack, TI Luanch Pad, and PIR motion detector sensor |

Now, Anaren have their Zigbee chip, Bluetooth chip and

finally the celebrated Bluetooth SMART chip. Since their first RF chip (CDMA,

900MHz) was soled at a humble price, and because taking this course helped me to know how to program

msp430 ( had to buy and use a TI msp430 lunch pad to do assignments!), I have

decided buy one of Anaren booster pack and play around with it. The booster

pack has two boards with Anaren RF chips, two microcontrollers pro-flashed with

Anaren software stack. Since the later is the most important part in Anaren

product, this post will mainly talk about programming the msp430 micro controller to do a certain task involving RF communication. First I had to

establish communication between the boards without adding any payload from an

external source, this was the easy part. See this link and picture below.

While experimenting with the booster pack, I needed payload

to transmit over the radio frequency link. There were many options including Boolean

one/zero, digital data from a sensor, analog data converted by microcontroller

to digital data stream. The choices are governed by the fact that booster pack

is best used with msp430 launch kit. My choice was a simple one/zero coming

from a passive infrared sensor (PIR sensor). You can buy PIR sensor from Radio shack or you can order it

from Parallex website. The sensor is made of a basic Pyroelectric sensor and a Fresnel lens covering the sensor; the later is made of a material that pass infrared spectrum between 8-14µm only. Pyroelectric sensor is divided into two half; each half will detect the infrared level on its side as shown below. When both sides reports same levels of infrared they will cancel each other out and no motion is reported. Now parallax claims a field of view (FOV)of 90 degrees; for a explanations of FOV you can see this link (one of my favorite blogs).

|

| Figure 2 Radiated Spectrum with Infrared light wave length marked |

The programming task of any application involving the booster pack is to allow the micro controller to send and receive data over the radio frequency link and in the same time process data coming from an external source. The normal solution to this problem was to use interrupts.

Since I had some cool project in mind, the following requirements were already set as the goal of my program:

Upon detecting motion, turn on a led,

As long as motion continues, keep led on,

If motion stops, do not turn led off until a certain time period has elapsed with no motion.